×

Single-use Bioprocess Products

Cell Culture Products

Protein Chromatography

Processing Filtration

Hydration Products

Single-Use Bioprocess Bags & Bottles

Single-Use Mixing System

Aseptic Connect & Disconnect

Aseptic Sampling & Filling

Bioprocess Supporting Vessels

Connectors and Fittings

Cell Culture Bioreactors

Cell Culture Bag

Cell Sorting

Cell Monitor

Microcarrier

Chromatography Column

Prepacked Column

Size Exclusion Chromatography Resin

Ion Exchange Chromatography Resin

Affinity Chromatography Resin

Hydrophobic Interaction Chromatography

Multimodal Chromatography

Polymer Chromatography

Filtration System

Filtration Filter

Filtration Holder

Water for Injection

Buffer Solution

Antifoaming Agent

BioHub® 2D Single-use Storage Bag

BioHub® 3D Single-use Storage Bag

BioHub® Single-use Freeze-thaw Bag

NovaLinX® Nuclease-free Single-use Consumables

HemoLinX® CFT Freezing Bag

BioHub® Single-use Storage Bottle

BioHub® Storage Bottle Tool Kit

BioHub® BM Single-use Magnetic Mixing System

BioHub® DS Single-use Desktop Mixing System

BioHub® UM Top-driven Mixing System

BioHub® FD Feeding System

BioHub® Single-use Powder-feeding Bag

BioHub® MB Single-use Mixing Bag

BioHub® Single-use Weighing Bag

BioHub® Sealer Ⅱ

BioHub® Sterile Welder

BioHub® Welder Ⅱ

BioHub® Sterile Cutter

BioHub® Single-use Sampling Bag

BioHub® Single-use Sampling Bottle

BioHub® Sterile Water Sampling Bag

BioHub® S Sterile Sampling Tray

BioHub® Single-use Filling System

BioHub® Fill Single-use Bulk Filling System

Circular Plastic Bin

Plastic Freeze-thaw Box

Cubic Foldable Plastic Bin

Cubic Stainless Steel Tank

Storage Tray

Storage Tray Transfer Cart

BioHub® Connectors

BioHub® Sanitary Clamp Fittings

Biohub® Hose Plug

BioHub® Diaphragm Gasket

BioHub® Clamp & End Cap

BioHub® Integrated Diaphragm Gauge Tee

SynaLinX® B-Flex™ Thermoplastic Tubing

SynaLinX® TST Platinum Cured Silicone Tubing

SynaLinX® HST Platinum Cured Silicone Tubing

CytoLinX® RW 10-200L Single-use Rocking Bioreactor

CytoLinX® GB 1-20L Benchtop Glass Bioreactor

CytoLinX® BR 10-2000L Single-use Bioreactor

CytoLinX® WB Single-use Cell Therapy Bag

CytoLinX® WB Single-use Cell Culture Bag

CytoLinX® BRTF Single-use Top-driven Bioreactor Bag

BioHub® Magnetic Separator

BioHub® Automated Bioprocess Analyzer

Puredex® Cyto-1 Microcarrier

Chrom-LinX® Lab-scale Empty Chromatography Column

Chrom-LinX® Manual Compression Chromatography Column

Chrom-LinX® Automated Chromatography Column

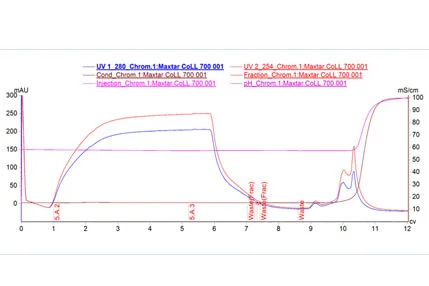

PuriLinX® Benchtop Chromatography System

VERDOT Ips² InPlace™ Process-scale Chromatography Column

ChromaX® Geldex® Prepacked Column

Chrom-Trap® & Chrom-Screen™ Prepacked Column

ChromaX® A20 Affinity Chromatography Column

Chromstar® FF Resin for Size Exclusion Chromatography

Chromstar® CL Resin for Size Exclusion Chromatography

Chromstar® B Resin for Size Exclusion Chromatography

Geldex® PG Resin for Size Exclusion Chromatography

Puredex® G Resin for Size Exclusion Chromatography

Puredex® LH-20 Resin for Size Exclusion Chromatography

Maxtar® Resins for Ion Exchange Chromatography

Maxtar® HR Resins for Ion Exchange Chromatography

MaXtar® HR XL Resins for Ion Exchange Chromatography

Chromstar® BB Resins for Ion Exchange Chromatography

Chromstar® FF Resins for Ion Exchange Chromatography

Chromstar® HP Resins for Ion Exchange Chromatography

Chromstar® XL Resins for Ion Exchange Chromatography

Puredex® Resins for Ion Exchange Chromatography

MaXtar® ARPA Affinity Chromatography Resins

MaXtar® rProtein A Affinity Chromatography Resins

MaXtar® Protein G Affinity Chromatography Resins

rProtein A Chromstar® FF Affinity Chromatography Resins

Protein G Chromstar® 4FF Affinity Chromatography Resins

Ni Chromstar® Affinity Chromatography Resins

IMAC Chromstar® Affinity Chromatography Resins

MaXtar® Chelating Affinity Chromatography Resins

Chelating Chromstar® FF Affinity Chromatography Resins

Glutathione Chromstar® Affinity Chromatography Resins

MaXtar® PlasmidCap HR Affinity Chromatography Resins

PlasmidCap Chromstar® HP Affinity Chromatography Resins

MaXtar® Heparin Affinity Chromatography Resins

Heparin Chromstar® Affinity Chromatography Resins

Benzamidine Chromstar® 4FF Affinity Chromatography Resins

MaXtar® Blue Affinity Chromatography Resins

Blue Chromstar® Affinity Chromatography Resins

NHS Activated Chromstar® 4FF Affinity Chromatography Resins

CNBr Activated Chromstar® Affinity Chromatography Resins

MaXtar® Hydrophobic Chromatography Resins

MaXtar® HR Hydrophobic Chromatography Resins

Chromstar® FF Hydrophobic Chromatography Resins

Chromstar® HP Hydrophobic Chromatography Resins

MaXtar® MMC Multimodal Chromatography Resins

Maxtar® MMA Multimodal Chromatography Resins

Hydroxyapatite BARONHAP® Type I&II Multimodal Chromatography Resin

PolyPSTM 50S

Maxgo® 30S

PolyPSTM Oligo dT (25) Pro Affinity Resin

Maxgo® 15/30RPC

FiltraLinX® Lab TFF System

FiltraLinX® Pilot TFF System

FiltraLinX® Benchtop Manual Hollow Fiber TFF System

FiltraLinX® Benchtop TFF System

FiltraLinX® Automatic TFF System

FiltraLinX® Manual TFF System

FiltraLinX® Semi-automatic TFF System

FiltraLinX® Benchtop Manual Cassette TFF System

Cernolix® Series KSG Hydrophilic Filters

VentiLink® Series ESG Hydrophobic Filters

Puruflon® FSG Hydrophobic Filters

Cruclix™ Hollow Fiber Filter

FiltraLinX® Depth Filter Holder (Type P3C)

FiltraLinX® Depth Filter Holder (Type M)

FiltraLinX® Virus Filter Holder

FiltraLinX® Tangential Flow Filtration Holder

HydroLinX® Water for Injection in Bottles

HydroLinX® Water for Injection in Bags

HydroLinX® Hydration Products

HydroLinX® Buffer Solutions and Process Liquids

HydroLinX® Antifoam Emulsion